Less oxygen, better quality

Pumping and mixing can introduce undesired air and gases that can compromise the quality of liquid food products, limiting their shelf life. Product deaeration – i.e. removing dissolved gases from water, carbonated beverages (CSD), juices, fruit puree and dairy products – offers the following benefits:

- Improved product shelf life and appearance, particularly color

- No oxidation of ingredients during heat treatment

- No impairment of flavorings, colorants or nutritional compounds

- Decreased foaming across all process stages

- Increased carbonation consistency

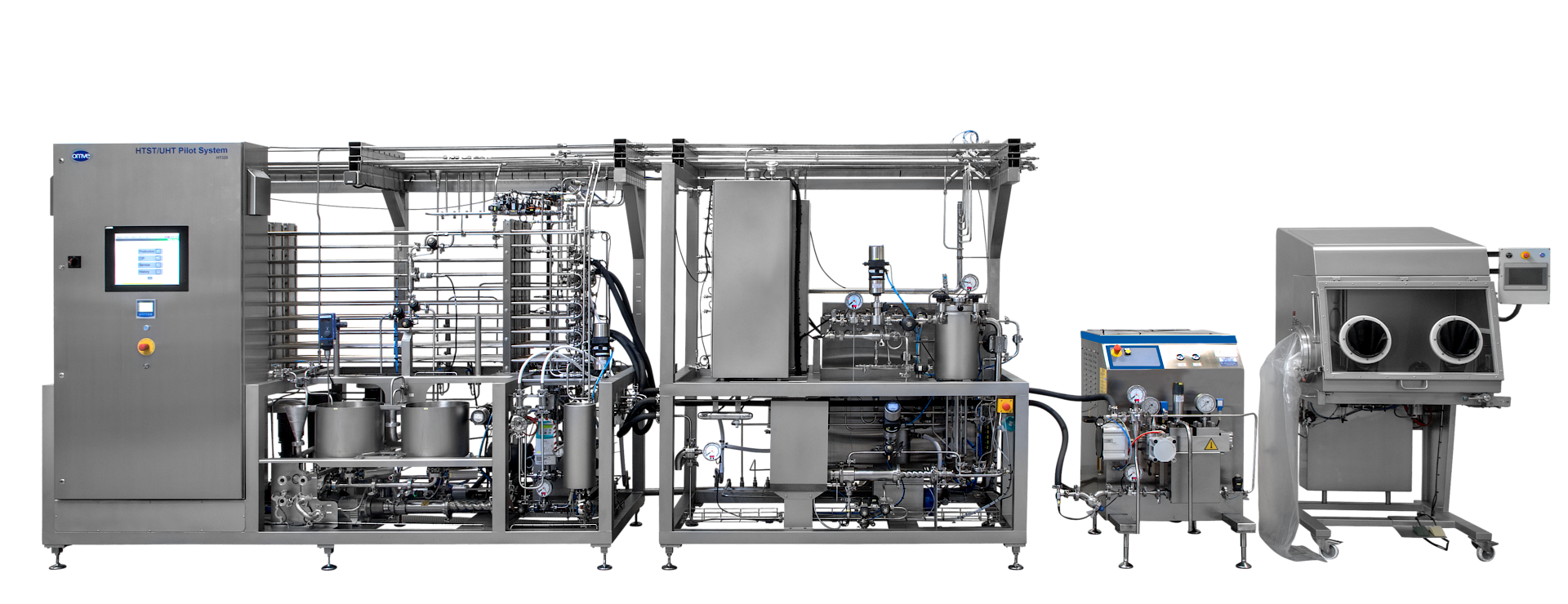

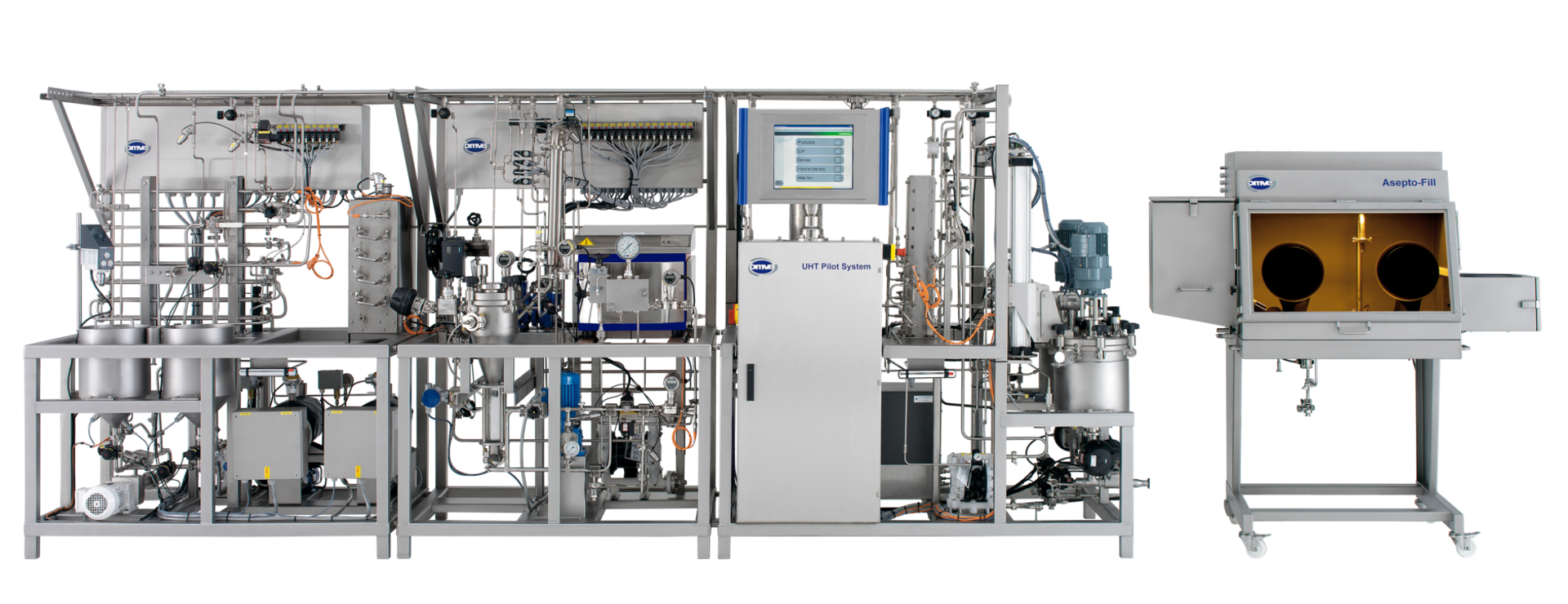

OMVE offers a range of inline and batch deaerators that mimic industrial deaeration processes to help you obtain similar results from R&D activities.

Our deaerators have a capacity range of between 10L/h and 1,000L/h.